The article summarizes many years of experience in geotechnical design, which was accumulated by GEOIZOL Project in terms of the use of bored injection anchor systems. First of all – own development of the GEOISOL Group of Companies – GEOIZOL-MP multifunctional geotechnical system (MGTS). The purpose of the investigation is to describe the technology and systematize a wide range of technical solutions using bored injection anchor systems: micropiles, ground anchors and dowel pins. It will allow design engineers to solve the geotechnical problems that arise before them more effectively.

Key words: bored injection pile, ground anchor, ground dowel pin, dowel fastening, slope strengthening, foundation strengthening, engineering protection of the territory.

Foreword

The multifunctional geotechnical system (MGTS) GEOIZOL-MP has been in use for ten years. The first Russian powerful anchor of size 105/52 was rolled at the Pushkin Machine-Building Plant (part of the GEOIZOL Group of Companies) on September 25, 2012.

When creating their own anchor system, the specialists of the Pushkin Machine-Building Plant focused on advanced Western developments, primarily Friedr products. Ischebeck GmbH.

Russian engineers managed to surpass their German colleagues. After cyclic testing, the loss of mechanical properties for GEOIZOL-MP anchors was 2.8%, against 4.4% for TITAN anchors [1]. The use of 40X grade steel makes it possible to additionally increase the mechanical properties of MGTS by 35-40%, which makes it possible to use GEOIZOL-MP in an especially strong design at facilities of increased responsibility.

MGTS GEOIZOL-MP is used in the construction of new and strengthening of existing foundations of buildings and structures, ensuring the stability of slopes and escarps, arranging the enclosing structures of pits, performing various measures of engineering protection of the territory and for solving other technical problems.

A review of the bored injection anchor systems presented on the Russian market and the possibilities of their use was carried out by employees of the Tyumen Industrial University [2], which, however, needs to be corrected and supplemented. We will consider the widest list of technical solutions and technology nuances using the design experience of the GEOIZOL Project company.

- Construction and technology for the implementation of MGTS GEOIZOL-MP

GEOIZOL-MP is a universal system that allows you to assemble and execute various geotechnical structures from a limited set of components: ground anchors, ground dowel pins, anchor bars or bored injection micropiles – a specific functional purpose is determined by the specifics of perceived loads and tasks to be solved.

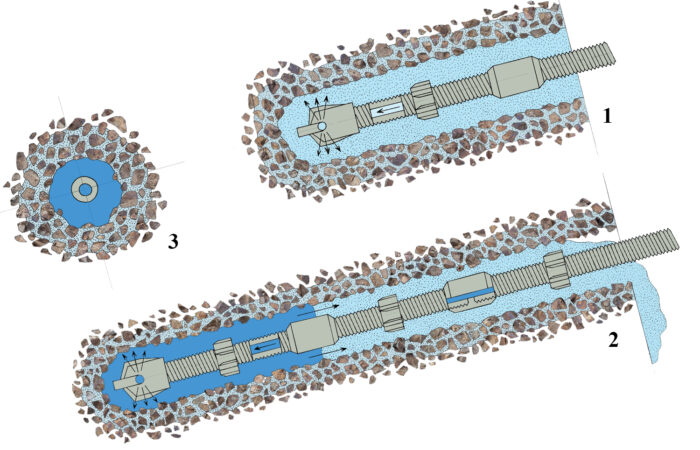

MGTS consists of hollow screw rods connected by couplings. The first segment is equipped with a drill bit (selected according to the type of soil) with nozzles. With a given step, centralizers are installed to place the shank at an equal distance from the walls of the boreholl. The configuration, composition and availability of fastening elements vary, depending on the purpose of GEOIZOL-MP.

Picture 1. Elements of MGTS GEOIZOL-MP: hollow screw rod (1), drill bit (2), coupling (3), centralizer (4), fastening elements (5)

MGTS GEOIZOL-MP is carried out within one technological cycle in two stages. A screw rod with a drill bit is used as a drilling and injection tool, and after penetration it remains in the boreholl as a reinforcing element.

At the first stage, drilling is carried out to the design depth with drilling cement mortar (W/C=0.7) fed into the well bottom through hollow rods and a drill bit with nozzles. The mortar cools the drill bit, ensures the removal of sludge, penetrates into the surrounding soil, strengthening the walls of the boreholl. The drilling mud fluid fills and stabilizes the boreholl, allowing drilling without borehole casings in any ground conditions. The drilling mud fluid outflow is taken into special containers and disposed of at landfills.

The geotechnical element is executed vertically or at any angle from 90° to 5° to the horizon. The use of injection packers makes it possible to perform MGTS horizontally and with negative angles to the horizon.

Picture 2. Stages of the MGTS GEOIZOL-MP device: drilling with mud fluid supply (1), injection of grouting mortar (2), section of the completed geotechnical structure (3)

At the second stage, a thick grouting cement mortar (W/C=0.4) is injected into the boreholl through the MGTS, which replaces the drilling mud fluid, and after development of strength becomes the body of a micropile, anchor or dowel pin.

A wide range of drilling equipment is used to perform the work: self-propelled drilling rigs, suspended equipment for universal and mining excavators, portable rigs for drilling in basements and other enclosed spaces, as well as small-sized mining drilling rigs that allow you to work on steep escarps using climbing equipment.

Technical solutions using bored injection anchor systems

Over the past 14 years, GEOIZOL Project has developed dozens of projects (all successfully passed the examination) using various bored injection anchor systems, including Western ones. Engineers have mastered not only advanced foreign design methods, but also carried out their own design developments in solving engineering problems. The design practice is reflected in the “Album of typical solutions for engineering protection of the territory” published in 2019 [3], which presents a wide range of structures, including those using bored injection anchor systems.

Below we will consider technical solutions in detail, structuring them depending on the functional purpose of the GEOIZOL-MP MGTS.

3.1 Ground dowel pin

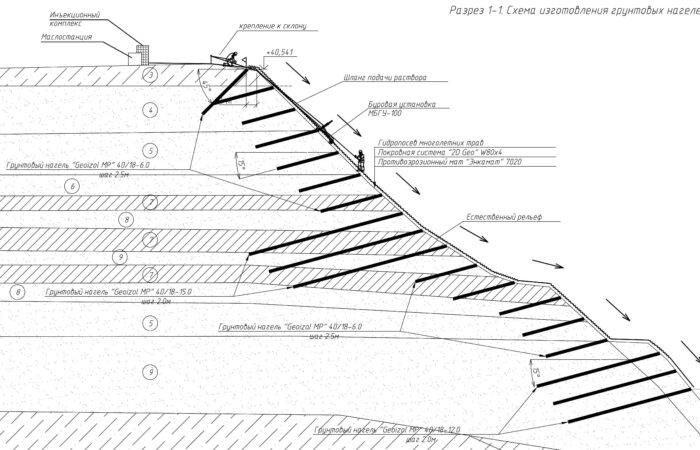

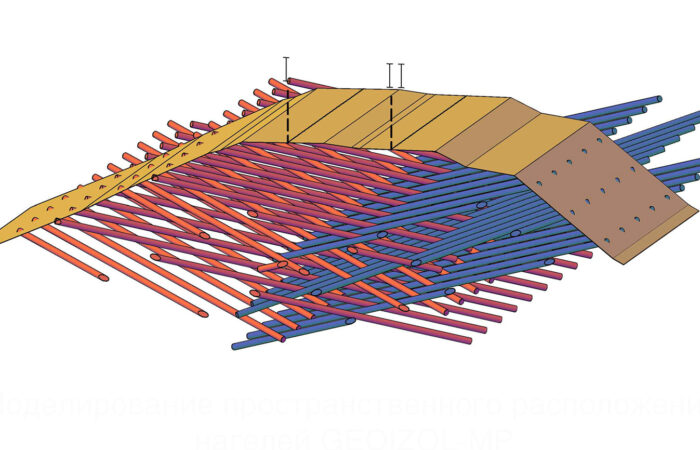

It is a nontensional geotechnical element that reinforces the soil. A group of inclined dowel pins (dowel field) is performed, as a rule, with a device on the surface of the covering system.

Dowel fastening – spatial reinforcement of the soil massif. Ground dowel pins go beyond the sliding surface of the slope, holding the soil mass, and are fixed in the underlying stable layers. The covering system prevents displacements on the surface and does not allow soil to fall out in the space between the dowel pins. The most widely used high-strength steel mesh in combination with erosion control blankets.

The solution is used when there are risks of landslide processes to ensure the stability of natural slopes and artificial slopes, including when changing the relief (developing deep excavations as part of road construction) or when placing objects higher up the slope.

In the summer of 2022, the dowel fastening was completed in the city of Svetlogorsk (Kaliningrad Region) on the coast of the Baltic Sea near the former Rus Hotel, on the site of which a large recreational center is being built. The solution, together with other measures of engineering protection of the territory, was widely used in the construction and reconstruction of the 7th and 8th stages of the federal highway A-291 “Tavrida” (Republic of Crimea). Dowel fields are made in order to ensure the stability of the supporting structures of the cable railroads K-1 – K-5 of the mountain climatic resort “Alpika-Service” on the slope of the Aibga ridge (Sochi, Krasnodar Territory). The number of implemented projects using this solution is in the tens.

The installation of dowel fastening is possible in rocky soils, which is important for mining enterprises. In this case, the dowel pins go beyond the boundary of the zone of possible collapses, fix large unstable rock blocks, and on the surface of the rocky and landslide area are united by a covering system of high-strength steel mesh, which prevents displacements on the slope surface and prevents stones from falling.

The anchor fastening of mine workings works in a similar way (including during the construction of tunnels). The steel mesh fixed with ground anchors provides a general overlap of the mine roof, prevents the soil from falling out and ensures the operability of the lining when individual anchors are torn off.

The creation of a spatially reinforced soil mass with the help of dowels can be used as a preventive measure in case of risks of developing karst processes under the existing embankments of roads and railways.

A unique feature of the solution is the ability to perform work without stopping the operation of the protected facility, for example, while maintaining train traffic. Such a kind of “flexible grillage” was made in the body of the embankment of the “Seima – Dzerzhinsk” line of the Gorky railway in the section km 395 – km 400 as part of anti-karst measures.

3.2 Ground dowel pin

It serves to transfer pulling forces from building structures (or fixed objects) into the soil. It is used as part of an anchor group or as a separate restraining element.

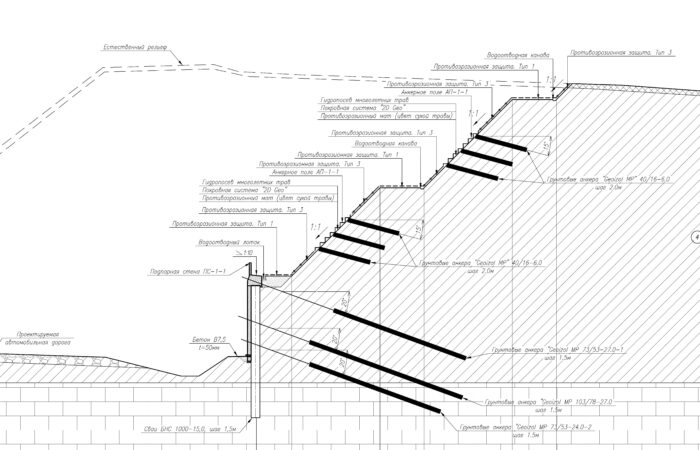

Anchors are widely used to additionally ensure the stability of both erected and as reinforcement of existing retaining structures for various purposes: retaining walls (sheet piling, piled, monolithic), bank-retaining structures (embankments, quay walls), etc.

To additionally ensure the stability of the pile retaining wall 10 m high in the deep excavation section, as part of the construction and reconstruction of the 8th stage of the Tavrida highway, 732 anchors 24-27 m long were made in two or three belts.

Picture 5. Pile retaining wall PS-1-1 with anchor fastening and dowel fastening made above. Federal highway A-291 “Tavrida” (section)

In the absence of surrounding buildings, it is possible to use anchor bolting to ensure the stability of the enclosing structures of pits (cut-off curtains), which makes it possible to abandon the use of cross-tie systems and ensure unimpeded excavation and subsequent work

In mountain conditions, ground anchors are used to secure equipment and machinery. For example, to ensure the safe movement of snowcats on steep mountain slopes.

Ground anchors are widely used for fixing various structures of engineering protection of the territory from natural hazards on the relief: mudflow-retaining, rock-trapping, avalanche protection barriers, anti-rockfall curtains, etc. For the installation of GEOIZOL-MP, light equipment is used, which allows you to work in hard-to-reach places, including on steep slopes, without the construction of technological access roads.

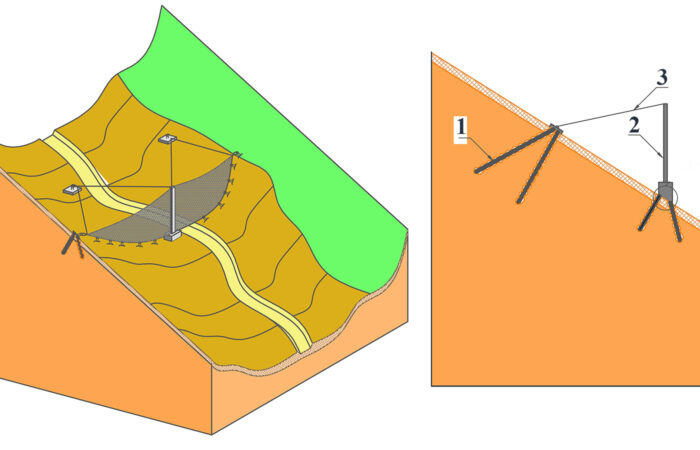

Picture 6. Mudflow barrier (general view and section): ground anchor (1), mesh barrier (2), rope guys (3)

A special case of such a structure is a mudflow barrier designed at km 17 of the federal highway P-297 “Amur” Chita – Khabarovsk (Zabaikalsky Krai). To place the structure within the boundaries of the road allotment, a mesh structure 10 m high and 360 m long was adopted, which is capable of absorbing significant loads, holding solid runoff during mudflow. To strengthen a powerful concrete base with a foundation of two rows of bored piles with a diameter of 800 mm and a length of 10 m, the project provides for the use of ground anchors GEOIZOL-MP 105/52 with a length of 19.5 m [4].

Anchor fastening with reinforced concrete pressure plates – own development of “GEOIZOL Project”. The solution is a compact alternative to the loading berm. Plates fixed with anchors create additional pressure (load) on the soil in the lower zone of the landslide body and increase the holding forces, thus increasing the stability of a potentially landslide slope or escarp.

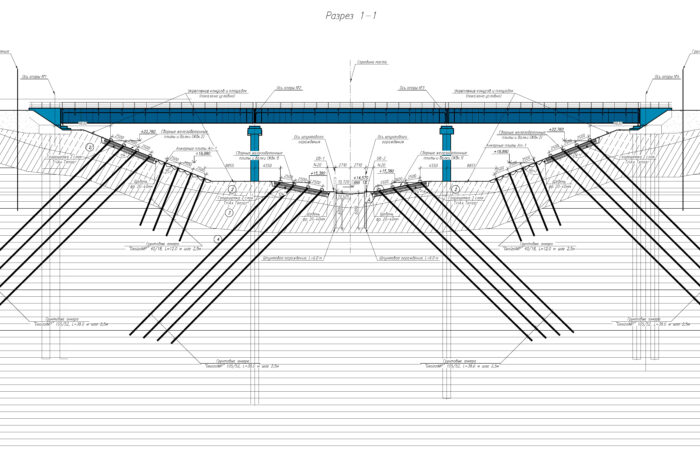

As a rule, the solution is used as part of anti-landslide measures. A special case is to ensure the stability of the cones of the bridge embankment at km 559 of the Obskaya-Bovanenkovo railway line (Yamalo-Nenets Autonomous Okrug). The emergency situation – the movement of coastal supports towards the channel – occurred as a result of the development of landslide processes provoked by the degradation of permafrost soils [5]. The project provides for the installation of three anchoring zones on each bank: one with pressure plates, fixed with GEOIZOL-MP 40/18 anchors, 12 m long, and two of precast concrete slabs, fixed with GEOIZOL-MP 105/52 anchors, 38 m long.

Picture 7. Scheme of strengthening the deformed cones of the bridge by anchoring with pressure plates (section)

3.3 Bored injection micropile

It is a bearing element that perceives pressing and / or pulling loads. Provides transfer of loads to a more solid foundation (to the supporting engineering-geological layer).

Bored injection piles make it possible to build foundations in cramped conditions and hard-to-reach places: during the construction of buildings and structures in dense surrounding buildings (including indoors), the construction of power transmission towers on mountain slopes, etc. In some cases, the installation of bored injection piles is the only cost-effective and technically implementable solution.

GEOIZOL-MP piles are characterized by a significant bearing capacity [6], which allows them to be used in the construction of large objects.

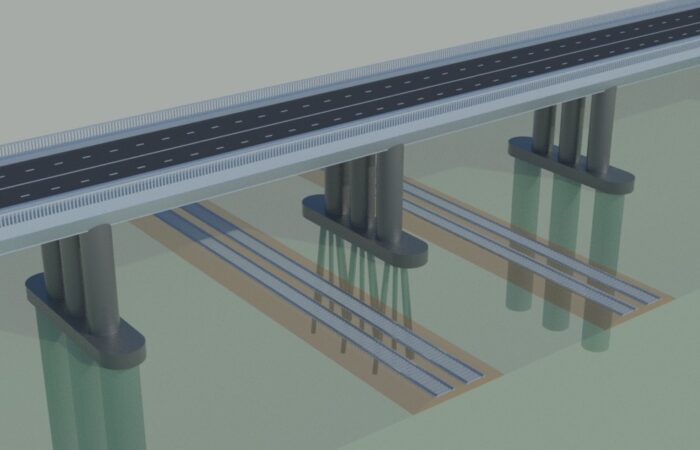

The project for the construction of an overpass in the alignment of Piskarevsky Prospekt in the area of the Ruchi railway station (St. Petersburg) implied the construction of a foundation of bored piles with a diameter of 1200 mm. Supporting structure No 12 was located in close proximity to the railway tracks and the work on the initially chosen technology would have required traffic to be stopped in a section with high traffic of freight and commuter trains. To avoid excessively high logistical costs, the project was adjusted and a variant with the installation of a cluster of bored injection piles was implemented.

Picture. 8. Visualization of the installation of a clump of bored injection piles under the overpass support

To minimize the negative impact of traffic restrictions, pile foundations using bored injection piles were adopted during the construction of an overhead pedestrian crossing at the intersection of Prospect Slavy and Budapestskaya Street (St. Petersburg). For the most loaded support, 4 vertical and 8 inclined bored injection piles GEOIZOL-MP-52/26 19 m long are provided.

Various solutions using bored injection piles are used to strengthen existing foundations, including as part of the reconstruction and restoration of cultural heritage sites. As a rule, when designing, two options are considered: transfer to inclined piles and / or to vertical piles with a system of connecting grillage.

In the first case, the piles are placed in a checkerboard order on both sides of the wall and are carried out at the design angle. Bored injection piles pass through the body of the foundation and are fixed in the bearing layers of the soil, transferring the load from the building to it. In the second, paired piles are made on both sides of the wall, which are then combined with a transverse reinforced concrete or metal spandrel beam.

If significant bending moments develop in the piles, to compensate for them, the wellhead zone of the bored injection piles can be additionally reinforced with steel pipes. It allows the use of MGTS in asymmetric schemes, as well as for organizing a pile foundation for foundations that perceive bending and horizontal loads.

The transplantation of the foundation on piles, in particular, is carried out in order to avoid unacceptable additional settlements of the building, including those associated with the reconstruction of the building itself, the development of the adjacent territory, or as a result of changes in the hydrogeological conditions of the site. First of all, this concerns historical buildings, for which strict standards apply: SP 22.13330.2016 “Foundations of buildings and structures” (Appendix K) in some cases allows vertical movements of no more than 5 mm.

The reconstruction project for modern use of the architectural monument – the barracks of the Pavlovsky Life Guards Regiment (St. Petersburg) – provided for the large-scale use of underground space, including the construction of an underground parking under the protection of the enclosing structure using the “wall in the ground” technology. The situation was aggravated by the presence of areas of weak soils up to 9 m thick under the rubble foundations. To exclude possible settlements, before performing the zero cycle works, the foundation was transplanted to GEOIZOL-MP inclined piles.

Bored injection piles can also be used as temporary auxiliary elements.

The reconstruction project with adaptation for modern use of another architectural monument – the Alexander Palace (GMZ “Tsarskoe Selo”, St. Petersburg) – provided for an increase in the volume of the basement floor by lowering the floor level by 1.6 m. To be able to perform work, the existing brick columns were temporarily hung on GEOIZOL-MP vertical piles, reinforced in the upper part with steel pipes, through a system of metal clips and beams. After the excavation of the soil to the design levels and the installation of a monolithic load-bearing floor slab, new foundations were laid under the columns, and temporary piles were dismantled.

Picture 10. Brick columns hung on GEOIZOL-MP temporary piles before laying new foundations. Alexander Palace

- Conclusion

Above is a wide, but not exhaustive list of technical solutions using bored injection anchor systems. The current generation of design engineers will have to expand it. With a creative approach, taking into account the capabilities of the multifunctional geotechnical system GEOIZOL-MP, they get an effective tool for solving specific geotechnical problems.

References

- Pushkin Machine-Building Plant. 100 years. – St. Petersburg, 2019. – 180 p. Documentary essay. – pp. 152-153.

- Samokhvalov Mikhail Alexandrovich, Geidt Andrey Vladimirovich, Paronko Alexander Alexandrovich Review of existing designs of bored injection anchor piles // Bulletin of MGSU. 2019. No. 12 (135). URL: https://cyberleninka.ru/article/n/obzor-suschestvuyuschih-konstruktsiy-buroinektsionnyh-ankernyh-svay (Date of access: 09/05/2022).

- “GEOIZOL Project”: site. – URL: https://geoizolproject.ru/library/albomy-tipovyh-reshenij/ (date of access: 09/05/2022).

- Aleksandrov P.A. Experience in the design and operation of anti-mudflow structures [Electronic resource] // site of the company “GEOIZOL Project”. URL: https://geoizolproject.ru/library/publikacii/opyt-proektirovanija-i-jekspluatacii-protivoselevyh-sooruzhenij/ (date of access: 09/05/2022).

- Bogdanov I.S. Engineering protection of territories, buildings and structures in permafrost conditions // Construction materials, equipment, technologies of the XXI century. – 2022. – No. 4 (273) – P. 57-61.

- Ermakov V.P. Evaluation of the work of rod piles-anchors, perceiving vertical and horizontal loads. Innovating science. 2017. No. 11. URL: https://cyberleninka.ru/article/n/otsenka-raboty-sterzhnevyh-svay-ankerov-vosprinimayuschih-vertikalnye-i-gorizontalnye-nagruzki (Date of access: 09/05/2022).