The installation of vibro-soil piles (“crushed stone piles”, pile-drains) is a technology for modifying the base soil by forming columns from inert materials in an array using the vibration compaction method.

Deep vibrocompaction increases the bearing capacity and reduces the deformability of the soil mass, reduces the time of consolidation and eliminates the subsidence properties of soils.

The technology is widely used in the construction of both infrastructural and industrial-civil facilities, mainly in new construction and reconstruction.

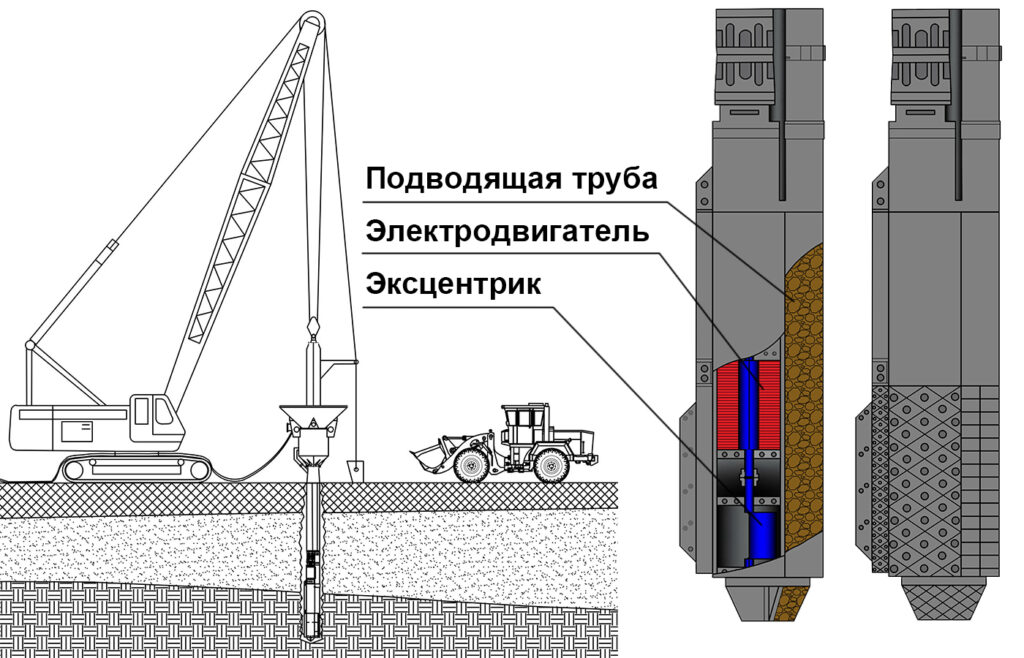

To perform the work is used: – vibroflot – deep floating vibrosystem; – crane for moving the vibroflot; – compressor for compressed air supply; – front loader or excavator for supply of filling inert material; – diesel electric generator (if it is impossible to connect to the high-voltage network).

The working body of the vibroflot is equipped with an electric motor with a connected eccentric weight, which provide vibration. A supply pipe runs along the vibroflot, through which air is supplied to the bottom of the well under pressure, and inert material is also supplied, from which the body of the vibro-soil “pile” is made.

* “UM GEOIZOL” has all the necessary equipment for the work.

- carry out “crushed stone piles” up to 30 m deep;

- vary the diameter of the “piles” from 600 mm to 1500 mm;

- ensure productivity up to 150 running meters per shift with one vibroflot.

Stages of performing a “crushed stone pile” (dry method with bottom crushed stone supply):

- – under the influence of vibration and compressed air, the vibroflot descends into the soil, forming a well to the design depth;

- – through the supply pipe, located parallel to the vibroflot, with the help of compressed air from the bunker, a portion of crushed stone is supplied to the bottom of the well;

- – vibroflot, moving up and down, compacts the crushed stone by means of vibration (the diameter of the well increases);

- – vibroflot step by step (translational movements up and down) rising up forms the body of the pile (one stage of compaction = one loading of the bunker with crushed stone).

Soil modification involves the construction of a field of “gravel piles” arranged in a given order. The work is carried out without excavation of the soil.

As a rule, in the process of vibrocompaction, externally directed radial stresses occur, which compact the soil and squeeze out pore water, due to which the element works like a drain pile: it does not interfere with the natural drainage of the soil, reduces pore pressure, and accelerates the consolidation of the base.

Columns made of inert materials, unlike reinforced concrete piles, are not separate load-bearing elements. Vibro-soil piles work as a whole with the improved soil, increasing its strength and deformation characteristics. Calculations are performed for the entire modified array. The name “crushed stone piles” (stone columns) was assigned to the technology for the most popular inert material. In addition to crushed stone, it is possible to use construction sand, ASG, concrete recycling and other materials.

Quality control is carried out in several stages. In the course of work, the on-board computer, taking into account the amount of crushed stone used and the parameters of vibrocompaction, determines the characteristics (including the geometry) of the crushed stone column and automatically generates a passport for each completed pile.

Possibilities and scope of “crushed stone piles” Vibrocompaction technology is applicable to improve the characteristics of most types of weak, weak water-saturated and organic-mineral (peat) soils, including those with thixotropic properties. Technology allows you to solve specific problems. The effectiveness of the technology application is determined by the specific conditions of construction. In some cases, the installation of “gravel piles” can achieve significant savings compared to other technical solutions.

Possibilities of “gravel piles”:

- 2-6 times reduction in subsidence of foundation soils;

- high speed of work execution;

- high speed of soil consolidation (begins in the course of work);

- relatively low cost of building material, possibility to use local resources;

- operation of piles as vertical drains;

- the possibility of modifying local sections of the base soil (ensuring the same deformability of soils throughout the construction area);

- the possibility of performing work in permafrost conditions.

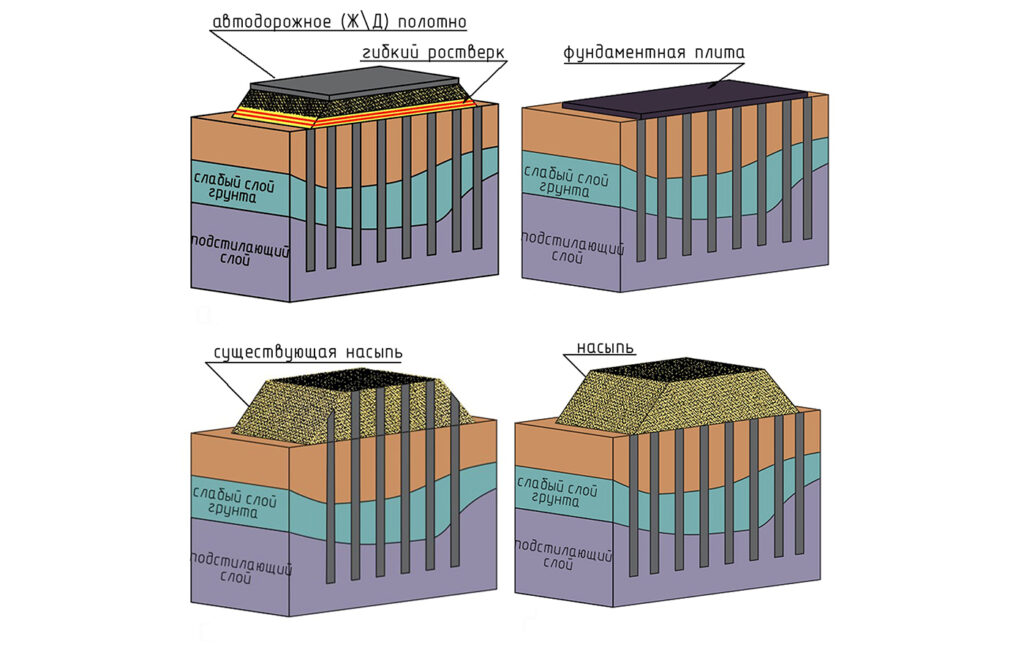

- arrangement of the foundation under the erected embankments of roads and railways;

- reinforcement of existing embankments (“crushed stone piles” pass through the body of the embankment);

- arrangement of foundations under the cones of embankments and abutments of bridges (in the shore zone of rivers and streams);

- stabilization of alluvial territories, banks of artificial and natural reservoirs;

- improvement of the soil characteristics of the foundations of buildings under construction (for the possibility of laying shallow foundations);

- arrangement of foundations for load-bearing floors (for large-span logistics centers and shopping malls).

Restrictions on the use of technology:

- significant vibration effects;

- the possibility of equipment mobilization;

- the impossibility of strengthening the foundation of existing buildings

The possibility of using soil reinforcement with vibro-soil elements is prescribed in SP 22.13330 “Foundations of buildings and structures”. Taking into account world developments, domestic standards and our own experience, GEOIZOL Project has developed all the necessary technical documentation and recommendations for the calculation, design and installation of crushed stone piles.

The technology has been successfully used at a number of industrial, civil and infrastructure construction sites, including the M-11 Neva and Central Ring Road highways, the Crimean Bridge, the Estel plant (Kolpino), the Bely Ostrov residential complex (St. Petersburg), the Lyubertsy Park residential complex (Moscow) and others.